- Home

- Weighing Solutions

- Grain Storage Solution (SILOS)

Grain Storage Solution (SILOS)

Optimal Grain Preservation for a Sustainable Future

Overview

With decades of expertise and cutting-edge R&D, Essae Digitronics is dedicated to elevating the standards of grain handling systems.

Our SILOS are engineered to safeguard your grain, reduce wastage, and enhance efficiency for a future-focused approach to grain storage.

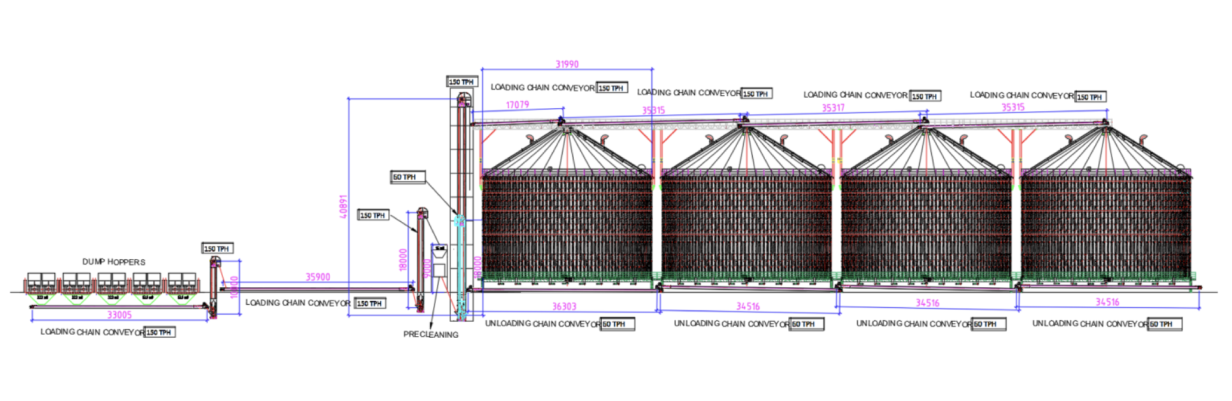

Process Flow Of Grain Handling

GRAIN

PROCESSED GRAIN

Why Choose Essae’s Grain Storage Solution?

Unmatched Durability

- Constructed with high-grade galvanized steel, our silos promise long-term resilience and weather resistance.

- Available in both Flat Bottom and Hopper Bottom designs, with capacities from 100 MT to 15000MT and material handling from 10 TPH to 350 TPH.

Innovative Design

- Constructed with high-grade galvanized steel, our silos promise long-term resilience and weather resistance.

- Available in both Flat Bottom and Hopper Bottom designs, with capacities from 100 MT to 15000MT and material handling from 10 TPH to 350 TPH.

Efficient Grain Handling Solutions

- Constructed with high-grade galvanized steel, our silos promise long-term resilience and weather resistance.

- Available in both Flat Bottom and Hopper Bottom designs, with capacities from 100 MT to 15000MT and material handling from 10 TPH to 350 TPH.

Safety and Accessibility

- Constructed with high-grade galvanized steel, our silos promise long-term resilience and weather resistance.

- Available in both Flat Bottom and Hopper Bottom designs, with capacities from 100 MT to 15000MT and material handling from 10 TPH to 350 TPH.

Customizable Solutions

All grain storage solutions are tailor made with customer interactions ensuring the end user’s applicational requirements to be on priority.

Types of Silos

Flat Bottom Silos

Capacity: 100 MT to 15000MT

Diameters: 4m to 40m

Materials: 350 to 600GSM galvanized steel(ASTM A 653 CLASS 1)

Fasteners: 10.9 grade Geomet 500 A plus

Hopper Bottom Silos

Capacity: 50 MT to 2000 MT

Diameters: 4m to 12m

Materials: 600GSM galvanized steel(ASTM A 653 CLASS 1)

Fasteners: 10.9 grade Geomet 500 A plus

Unique Features

Silo Roof

Guarantees exact weight, consistently delivered with unfailing accuracy, ensuring error-free results.

Ladders & Platforms

Safe access with bolted ladder designs, safety cages, and intermediate rest platforms.

Stiffeners Support

“W” type vertical stiffeners and multiple rows for bearing higher vertical loads.

Design Parameters

Capable of with standing wind loads of 144Kmph to 225Kmph and seismic loads of 0.25g/Zone V.

Silo Wall

High yield corrugated walls with ultra-high tensile strength.

Grain Handling & Conditioning

Our comprehensive grain storage solutions include advanced handling and conditioning systems to ensure safe and efficient grain management.

Chain Conveyor

- Highly efficient solutions depending on type of grain which is to be conveyed at required speed

- 300GSM. galvanized steel structure which is corrosion resistant. easy installation, maintenance and repair with bolted construction.

- special Bearings with oil seals are nodular cast iron and resists harsh negative ambient conditions,

- Linear UHMWPE bearing is used to reduce friction during the chain movement reducing resistance and encouraging silent operation.

- Grain level can be monitored through level monitoring windows on conveyors.

Bucket Elevator

- Bolted connection in the structure facilitates easy installation and maintenance.

- Use of engineering plastics in elevator buckets enables a smooth OPERATION

- Long-lasting use due to LOW resistance to wear, heat and corrosion.

- Centrifugal discharge efficiency is increased by making bucket selection as per the crop type and conveyance capacity.

- UHMW PE used to aid grain flow, this helps to increase wear resistance and replaceable.

- Heavy-duty roller bearings on drive heads and shafts hardened in stages helps to extend lifespan of moving parts.

- Removable drum, shaft connection and removable rubber coating on the drum provide ease in installation and maintenance.

- Latch covers for inspection provide ease during monitoring, maintenance and repair in case when necessary.

Belt Conveyor

- A belt conveyor system can be implemented with a very economical cost per foot of the conveyor for many warehouse and industrial applications. Because it includes just one motor and a simple belt system they are quite simple. Hence we design based on the requirement

Sweep Augers

- A spiral unloader or conveyor are used to unload crops on the silo base completely. These are specially designed equipment for extracting leftover inside the silo after grain is unloaded to a certain extent with its own flowing force. They can be manufactured from galvanized steel, painted steel or stainless steel as required by customers. The basic material is high grade steel. It conveys crops fast and smoothly without any problem. It is recommended for use twice or three times a year.

Advantage Over Warehouse

For the storage of paddy rice, warehouse storage has a lower initial cost vs. Silos. However, theinitial cost benefit is deceptive because warehouses could incur material losses in the form ofrodent, bird and insect infestation, absence of effective aeration systems and temperature monitoring system, which could give an early warning on grain spoilage. The manpower costs to maintain the ware house could be an expensive affair in long run.

On the contrary, a silo storage system in long run would be more economical, efficient ensuring the right product quality offered by silo subsystems such as temperature monitoring system monitoring grain temperature at various levels giving an indication of spoilage in case it happens, aeration system controlling grain humidity by restricting it within specified ranges

thereby preventing spoilage and maintain right quality, fumigation system which acts as a rodent

repellant thereby preventing contamination and grain spoilage.

In the long run the silos will make the rice miller more profit due to the reduction of spoilage and a better milling quality. Almost all modern rice mills today use silo storage.

Quality Standards and Endorsements

Trusted by Industry Leaders

Since 1965, Essae Digitronics has been a name synonymous with quality and innovation.

Our SILOS are crafted to ensure your grain is preserved in optimal conditions, maintaining its quality and value.