Truck Weigh In Motion

Accelerate with Accuracy

Play Video

Essae Steel WB

Overview

Robust, Reliable and Proven Technology Solutions for high-speed and low-speed weighing, overload detection, toll roads, mines, sea ports, and bridge protection.

At Essae Digitronics, we proudly introduce our state-of-the-art Truck Weigh-In-Motion (WIM) System – a game-changer in the world of weighing solutions. Our WIM system is meticulously designed to revolutionize the way you manage and optimize vehicle weight measurements, ensuring compliance, efficiency, and safety in various industries.

Our Truck Weigh-In-Motion System is a technological marvel that seamlessly integrates into your existing operations, providing real-time, accurate weight data for vehicles in motion. With minimal disruption to traffic flow, this innovative solution offers a host of benefits for various applications, including logistics, transportation, and regulatory compliance.

Features

Enabling manufacturers to win

Real-time Accuracy of ± 1% to ± 2%. Ensures compliance, minimizes overloading risk with precise vehicle weight measurements.

Maximize Operational Productivity and Cost Savings: Eliminate traditional static weighbridges, saving time and resources.

Access weighing data reports conveniently through various interfaces, including PCs, Ethernet connections, and the Internet, enhancing accessibility and convenience.

Comprehensive services spanning design, manufacturing, installation, and post-sales support available at 86 nationwide locations.

Improved Efficiency: Experience reduced wait times and increased throughput with our efficient, non-intrusive weighing technology.

Data Integration: Easily integrate weight data into your existing systems, enabling better decision-making and comprehensive reporting.

Enhanced Safety: Promote safety on the road by preventing overweight vehicles from causing accidents and road damage.

Dynamic Load Monitoring: Continuously monitor and alert for sudden changes in load distribution, ensuring safer and efficient operations.

Models with features

Irrefutable Solution for Trucking Terminals

Trucks with axle load higher than legal limits cause a disproportionately higher percentage of damage to the infrastructure and adverse impact on traffic safety. Essae Truck Weigh in motion System (TWIM) is a robust, reliable, maintenance-free weighing mechanism designed for use on highway entries with non-stop heavy traffic. Weighing accuracy and performance are approved for trade use and for law enforcement purposes.

When speed is critical and vehicle weighing is an integral part of the operation, Essae TWIM system provides significant cost savings over full-platform and axle scales. The vehicle loads (wheel, axle, GVW, load ratios) are automatically analysed, compared to legal limits and results are displayed on operator’s PC monitor, the driver gets the corresponding printout and the data are also recorded for further reporting or can be sent via LAN or Internet to the server.. This minimizes operator’s mistakes, offers inbuilt data protection and allows vehicle throughput up to 180 vehicles per hour.

TWIM for Toll Plaza, Toll Roads and Bridges

The vehicle weight, not the number of axles, determines wear and tear of roads. Toll authorities now use weight-based tolling, which relies on weigh in motion technology to determine the proper toll classification while keeping the traffic movin.

Essae Automatic TWIM weighing system

Its rigid construction significantly improves scale reliability in heavy-duty operation and helps to achieve precise positioning into the road during installation thus reducing the installation costs. The weighbridge is connected to traffic lights and signal horn to control vehicle movement. Video camera for vehicle detection and vehicle image capturing can be delivered as optional equipment.

Key Benefits

- Instant check for road legal weight

- Fully unattended weighing operation

- Weighs hundreds of vehicles daily

- Daily reporting measures vehicle productivity

- Automatic recording of weight and images of vehicles

- Gross weight, axle weights, numbers of axles can be recorded

- Data records can be stored for future use or can be sent via LAN or Internet to the server.

TWIM for Seaports

Essae TWIM system provides the ability to weigh thousands of containers prior to loading onto ships without the delays caused by trucks stopping at static scales.

TWIM for Border Crossings

The vehicle weight, not the number of axles, determines wear and tear of roads. Toll authorities now use weight-based tolling, which relies on weigh in motion technology to determine the proper toll classification while keeping the traffic moving.

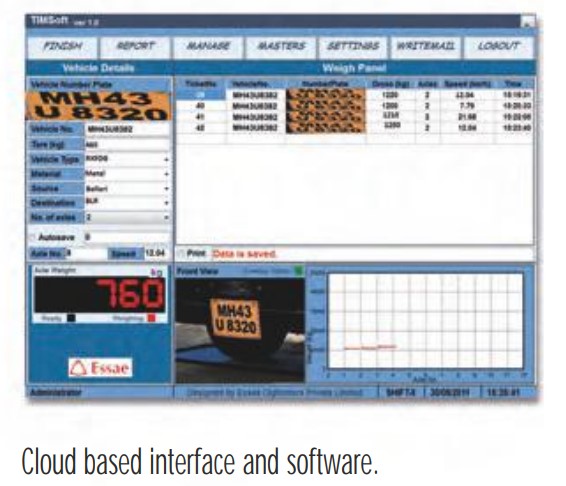

Software

The Proprietary software ensures fully automatic weighing. Advanced functions like the Vehicle Weighing configuration and classification, law compliance checking, fines computing, or LEF calculations are implemented without any additional costs for the user.

- Web based architecture with visualization on real time.

- Communication options – GSM/ GPRS, RS232, TCP/IP Wi fi.

- Runs on standard web browser.

- Flexible protocols.

Lightening Protector

- Protects load cells against transient surges caused by lightening

- Repeated auto re-setting operation without maintenance

- Reliable protection through high surge absorption capacity

- No effect on system accuracy

Specifications of Truck Weigh In Motion

| Capacity | 120 tons |

| Accuracy of weighing | ±1% to ±2% of the gross weight |

| Platform size | 845 mm × 3275 mm (Outer Dimension) |

| Type of In-Motion Scale | Load cell based permanent In-motion scale |

| Type of Installation | Pit Type |

| Speed of weighing | 0 KMPH to 15 KMPH |

| Type of Recording | Automatic, Un-manned Recording |

| Direction of weighing | One Direction |

| Cables | 4 core shielded with SS Armor protection |

| Operating Temp. & Humidity | -5°C to +60°C and 95% RH |

| Power Supply | AC single Phase 230V, 50 HZ |

| Type of Reports | Date, Time, Location, Weight & Speed of the vehicle |

| Material of the Platform | Mild Steel IS 2062 painted with epoxy & enamel paints. |

| Life of the Machine | 8 to 15 yrs. |

| Optional | Can also be connected to Camera for recording to weight along with photograph of the vehicle |

| Hardware Specifications | PC Requirements for LPE camera & Software – Windows XP SP3 Operating System, Intel Core2Duo processor with 2.8GHz or faster, minimum 2GB RAM, with Ethernet |