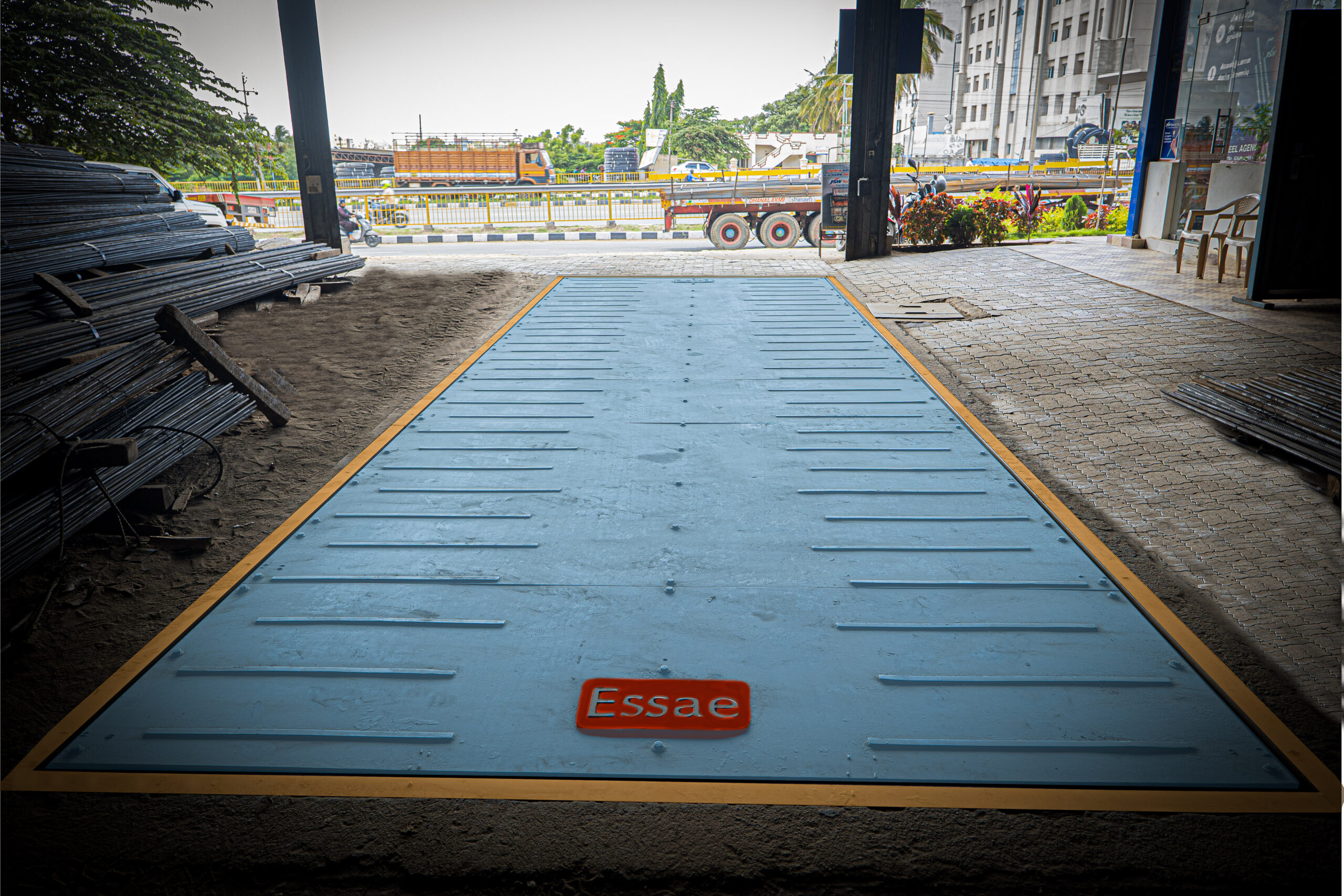

Steel Weighbridge

Engineered To Take Loads Off Your Mind

Play Video

Essae Steel WB

Overview

Our steel weighbridge decks offer higher strength, greater reliability and faster installation than conventional systems.

Their simple foundations, fast, bolt-down sitting and innovative box construction have made them the preferred choice of operators across the country. You can choose either a Surface Mounted or a Pit Mounted Truck Scale depending on the space availability.

The platform of the truck scale is designed to withstand harsh environmental conditions. Latest machines are deployed to ensure that quality is built into the manufacturing process. The production system ensures impeccable focus to the performance of the product and faster response to customer’s needs.

Features

Enabling manufacturers to win

High Load Capacity: Robust steel construction supports heavy loads for accurate weighing.

Quick Setup: Fast, cost-effective installation reduces downtime, improving operational efficiency.

Rust Resistance: Shot-blasting and epoxy paint ensure long-lasting corrosion protection in any environment.

Precision Manufacturing: Advanced machinery and stringent quality standards guarantee reliable performance.

Superior Steel: High-quality steel enhances sectional efficiency, boosting load-bearing capacity.

Advanced Techniques: Plasma Cutting, MIG Welding, NDT Testing, Shot Blasting, and Protective Coating ensure quality.

Pre-Delivery Calibration: Rigorous testing ensures accurate measurements right from installation.

Dependable Reliability: Steel weighbridges provide consistent, trustworthy results for various weighing needs.

Models with features

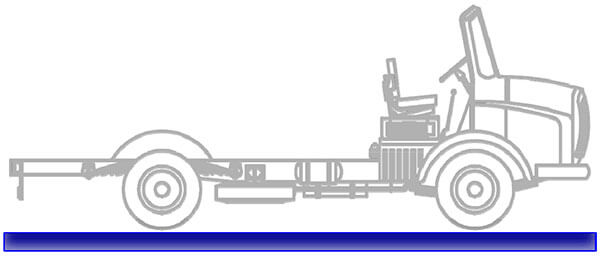

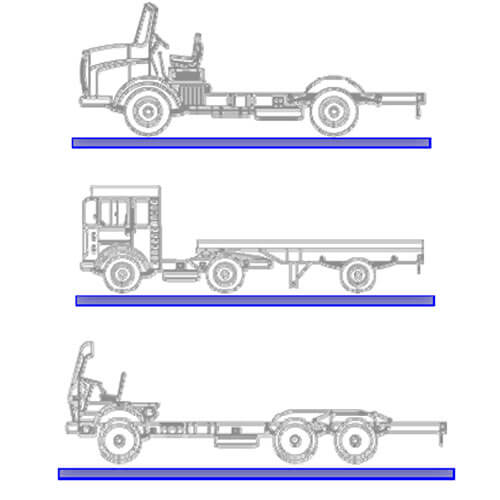

Pit Weighbridge

- Less space consumption

- Level with pavement

- Easy access to weighbridge

- Easy access to weighbridge components

Pitless Weighbridge

- Less Civil Expense

- Visibility of Weighbridge

- No water clogging problem

- Easy maintenance

-

Platform size 7.5m x 3mCapacity ( in tons) 40, 50, 40, 50

TATA ASHOK LEYLAND: 407/31 407/31 407/31 407/31 SFC 609 SFC 609 Se1510A/32 Se1510A/32 SE 1510/32 SE 1510/32 LPT 1510/31 LPT 1510/31 LPT1510A/32 LPT1510A/32 L1210D/32 Haulage L1210D/32 Haulage -

Platform size 9m x 3mCapacity ( in tons) 40, 50, 60, 40, 50, 60

LPT 1612/48L1210D/32 Haulage407/31LPT 1612/48L1210D/32 Haulage407/31LPT 1612/48L1210D/32 Haulage407/31LPT 1612/48L1210D/32 Haulage407/31

TATA ASHOK LEYLAND: Others LPT 1510/36 & LPT 1510A/36 TUSKER 13C 47 SK 1612/36 LPT 1510/36 & LPT 1510A/36 CARGO 75.12 LPS 1616/32 + STP-2-35 LPT 1510/48 & LPT 1510A/48 CARGO 1614 & CARGO 909 SE 1510/36 & SE 1510A/36 COMET 1611 SE 1510/42 & SE 1510A/42 AL-CO 3/1 & 3/2 Haulage SE 1510/48 & SE 1510A/48 BEAVER AL-B 1/1 Haulage LPT 1612/42 HIPPO AL-H 1/4 Tractor LPT 2213 & LPT 2416 LPT 1613, LPT 709/34 & LPT 709/38 L1210D/36 & L1210D/42 -

Platform size 12m x 3mCapacity ( in tons) 50, 60, 100

VOLVO Mercedes Others All FM & FH series ACTROS 4841K LPS1616/32 +CC-2-20 LPS 1616/32 + TC-1-10 LPS 1616/32 + VTT-2-30 LPS1616/32 + TSS-2-10 LPS 1616/32 + TC-1-20 LPS 1616/32 + TSS-2-10 -

Platform size 15m x 3mCapacity ( in tons) 50, 60, 100, 120

VOLVO Mercedes Others All FM & FH series ACTROS 4841K LPS1616/32 + LB-1-25 LPS 1616/32 + FB-1-20 LPS 1616/32 + LB-1-20 LPS 1616/32 + FB-1-10 LPS 1616/32 + TSS-3-40 LPS 1616/32 + SSFR-2-50 LPS 1616/32 + TSS-3-30 LPS 1616/32 + LPS 1616/32 + STN-2-40

-

Platform size 18m x 3mCapacity ( in tons) 60, 100, 120, 150

VOLVO Mercedes Others All FM & FH series ACTROS 4841K LPS1616/32 +SSF-2-40 LPS 1616/32 +SSFR-2-60 LPS 1616/32 +STN-2-25 LPS 1616/32 + FB-2-40 LPS 1616/32 +CC-2-40 LPS 1616/32 +FB-2-25 LPS1616/32 + TSS-2-20 LPS 1616/32 + TU-4-40 LPS 1616/32 + STP-2-35 LPS 1616/32 + SSF-2-25 LPS 1616/32 + TU-4-30 LPS 1616/32 + DDF-2-20

Construction Process of Steel Weighbridge

Step 1

Civil Construction

Step 2

Assembly of Beams

Step 3

Wielding of Base Sheets

Step 4

Laying of

Re-enforcement

Step 5

Concrete Pouring & Leveling

Step 6

Installing the Load cells

Seven Key Differentiators

-

100% Guaranteed Accuracy

Each load cell of a weighbridge is calibrated & tested to full capacity at the plant before being sent to site.

-

Superior Manufacturing Practices

Plasma Cutting

Superior Steel

Shot Blasting

MIG Wielding

ND-Testing

Red-oxide Coating

Epoxy Paint

-

Best-in-class Indicator

- Factory calibration restore function

- Standalone operations possible without connecting to PC

- Over 20,000 records can be stored, processed and retrieved facilitating an effective truck data management

- RS232, RS485, Ethernet and networking interface

- Standard alphanumeric keypad for faster data entry

- Can be directly connected to the printer

- PS2 keyboard connectivity (Optional)

-

Double Ended Shear Beam Load cells

- Self-checking & center loaded single link design

- Eliminates Friction & Provides Free movement in horizontal position

- Unique Mounting system- protects the Load cells from Side load Shocks

- Eliminates excess movements of the platform

- Pendulum action of the link automatically centers itself

-

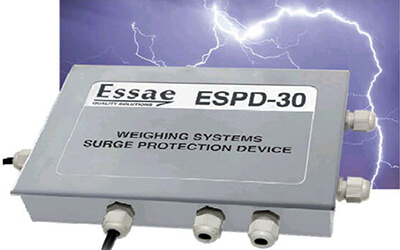

Lightening Protector

- Protects loads cells against transient surges caused by lightening

- Repeated Auto re-setting operation without maintenance

- Reliable protection through high surge absorption capacity

- No effect on system accuracy

-

WeighSoft Enterprise

- Supports Oracle, My-SQL, MS-SQL, SYBASE, POSTGRE SQL

- Online, Offline, & Single Point ticket transactions

- User can define data fields to captured for the ticket

- Allows entry of Material, Supplier, Vehicle, & shift details

- User can create formula fields

- View reports based on specific queries

- Well defined security mechanism for different levels of users

- Web Camera Integration

- Compatible to ERP/SAP

-

After-sales Support

- Over 86 Service Engineers across the country

- 93% of ESSAE installations can be reached within 3hrs

- Central Repository of Customer Information

- Follow-up and automatic escalations till customer tickets are closed

- Call Centre with ONE contact number across the country to manage customer concerns

Explore projects Details