Rail Weigh In Motion

Track Your Weight, On the Track

Play Video

Essae Steel WB

Overview

Weighing plays a crucial role in cost control and safety across various business operations, from monitoring product deliveries to avoiding overloading penalties.

Often situated in remote or challenging environments, weighing systems must be implemented with minimal disruption to regular traffic flow. Freight may need to be weighed at high speeds, as many customers utilize a wide range of locomotives and rolling stock.

Essae Digitronics, one of the country’s leading weigh scale manufacturers, boasts the largest number of operational in-motion Weighing Systems nationwide, offering solutions to address the challenges associated with weigh-in-motion concerns.

Features

Enabling manufacturers to win

High-Speed Sampling: Achieves up to 52,000 samples/second for precise weight measurement.

Exceptional Precision: 24-bit A/D with ±8 million counts ensures accurate tension and compression measurements.

Powerful Processing: Equipped with a 32-bit/135 MIPS DSP for rapid onboard data processing.

Versatile Integration: Ideal for OEM applications, enabling seamless board embedding for various uses.

Clear Display: Features an 8-digit LED display for easy weight reading.

Temperature Monitoring: Onboard temperature sensor ensures reliable performance in varying conditions.

Connectivity Options: Multiple boards can be linked via USB or RS485 for flexibility.

Certified Quality: RDSO and OIML approved, suitable for industrial applications nationwide and internationally.

Models with features

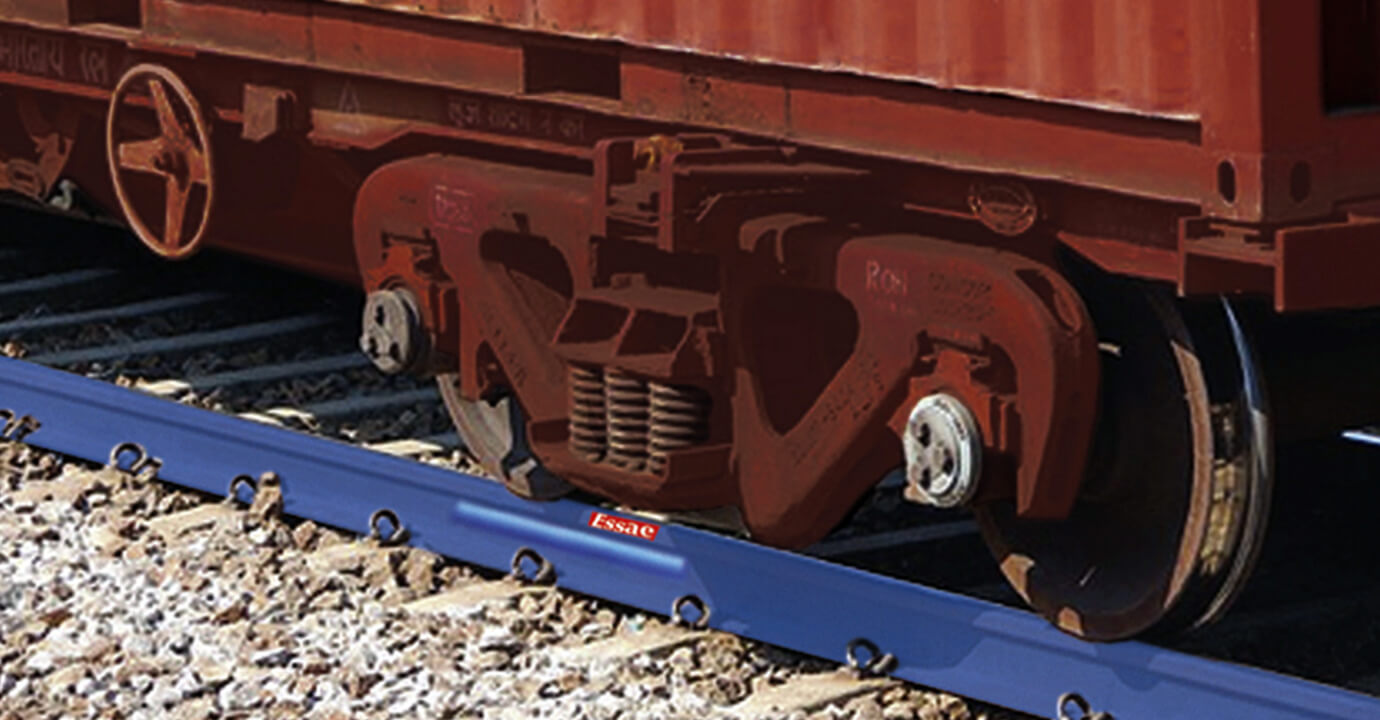

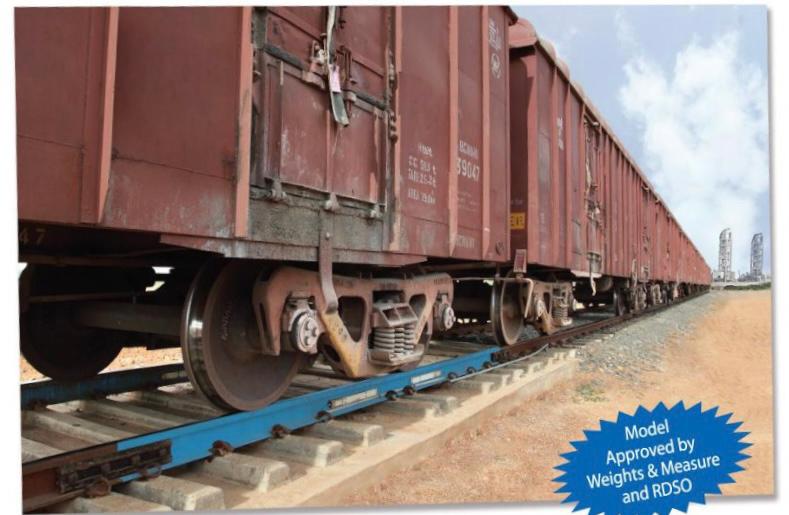

Rail Weigh in Motion (Rail-WIM)

Our Rail Weigh in Motion system is RDSO approved and a tailor-made train weighing solution that is easy to install at a low cost. Our team of experts develops and provides solutions for all rail users, from raw material procurement to end-users. Our microprocessor-based modular electronics, combined with high-quality strain gauges from the USA, ensure high accuracy even at varying speeds. The system can be designed for static and/or in-motion weighing of wheels, axles, bogies, and full draft weighing of locomotives and all types of rolling stock.

Rail-WIM provides precise data on rack and wagon weights, which can be seamlessly integrated with the client’s business systems through PCs, Ethernet, or the Internet.

By automatically detecting wheel, axle, and wagon overloads, this system helps identify imbalanced loads and prevents multiple weighments of the same vehicle, ensuring safety and avoiding overloading penalties.

RlMsoft: A Comprehensive and Smart Solution

Essae provides its proprietary software, ‘R|Msoft,’ which assists in obtaining weigh details in the desired format. It generates, stores, and prints reports of weigh data.

These reports can be linked to individual wagons, loads, and destinations, enabling you to monitor deliveries to and from customers and suppliers effectively.

Additionally, each machine comes with calibration software, allowing users to calibrate the weighbridge for different weather conditions, ensuring accurate weighing every time.

Lightning Protector

- Protects load cells against transient surges caused by lightning.

- Performs repeated auto-resetting operations without the need for maintenance.

- Provides reliable protection with a high surge absorption capacity.

- Has no adverse effects on system accuracy.

Specifications of Weigh Rails

| Weigh Sensors | Embedded Rail Mounted Strain gauge Sensors |

| Design | Pitless Type |

| Capacity | l20MT/ l50MT for Standard wagons |

| Resolution | lOKg/20Kg/50Kg/l00Kg |

| Selectable | Digital calibration torTare, Zero, Gain,Calibration Auto Zero and gain Check |

| Accuracy | 10.5% for Individual Wagon and :0.2% for Unit Train Weigh Bridge : Suitable for 52Kg / 60Kg Track Grade Rails Length 5.5mWeighing Speed : Upto 15 kmp/h, Non Weighing upto 40 kmp/h as limited by Railways |

| Track Switches | Optical Proximity |

| Wagon ID | All Types of 4 axles / 2 axles |

| Elimination | All types Diesel / Electric Locos |

| Direction | Bi-directional Weighment |

| Electronics | DIP based very High Speed Signal Processing |

| Interface | Through USB / RS232 |

| Printout | Date 8: Rake » wise and Date & Shift 8: Rake – wise reports |

| Computer | Windows XP: any lntel Core processors, 1GB RAM, 40GB HDD |

| Software | Visual Studio .NET 2008 windows based application, Crystal Report and MS Access Database |

Other Applications

- Static rail cum road weighbridge

- Torpedo Weigh In Motion (800 tons)